Basic Info

Model No.: GLZ

Click on the follow link to find out more information: https://www.ytdryer.com/ribbon-vacuum-dryer-machine/

Company Info

- Company Name: Jiangsu Yutong Drying Engineering Co.,Ltd

- Representative: lu wenguang

- Product/Service: Spray Dryers , Flash Dryers , Mixing Machines , Granulating Machines , Grinding Machines , Vacuum Dryers

- Capital (Million US $): 108,0000RMB

- Year Established: 2000

- Total Annual Sales Volume (Million US $): US$10 Million - US$50 Million

- Export Percentage: 11% - 20%

- Total Annual Purchase Volume (Million US $): US$10 Million - US$50 Million

- No. of Production Lines: 12

- No. of R&D Staff: 11 -20 People

- No. of QC Staff: 5 -10 People

- OEM Services Provided: yes

- Factory Size (Sq.meters): Above 100,000 square meters

- Factory Location: Shunehe Road68 ,Jiaoxi, Zhenlu Town, Wujin District, Changzhou City, Jiangsu Province, China

- Contact Person: Mr. Andrew

- Tel: 86-138-61087188

Email to this supplier

Premium Related Products

Hot Products

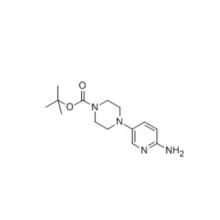

Organic pigment and dye raw material 4-Chloro-2-nitroaniline CAS 89-63-42-Amino-4-chloro-5-methylbenzene sulfonic acid, cas no 88-51-7, C7H6ClNO3S100% Pure Natural cosmetic raw material and whitening alpha Arbutin alpha-arbutinGMP CERTIFICATE MANUFACTURER FOR ASPIRIN RAW MATERIAL SALICYLIC ACID,CAS NO.:69-72-799.5% Arbutin Cosmetic whitener2-Nitro-1,4-Phenylenediamine cas:5307-14-2VE / GMP Certified Vitamin E Acetate Bulk Vitamin E Oil5-BROMO-5-NITRO-1,3-DIOXANE Cas No: 30007-47-7 the other name M-DIOXANE,5-BROMO-5-NITRO-(8CI)white crystalline powder allantoin with CAS 97-59-6Cosmetic Preservative Diazolidinyl Urea Cas No.:78491-02-8 the other name DiazoalkylureaHigh quality 99-76-3 methyl paraben pricerefined grade Adipic Acid 99.7%min Cas No.: 124-04-9Avobenzone CAS NO.:70356-09-1Trimethyl Ortho Formate, TMOF, CAS No. 149-73-5Triethyl Ortho Formate CAS No. 122-51-0131-57-7 Ultraviolet Absorber UV-9 (BP-3) Benzophenone-3